EEA Electrical Engineer Contributors: Robert Davis, PE; Mark Kostroun, PE

Electrical Safety has advanced greatly throughout the years, but the destructive potential of electricity can still rear up if its hazards are not understood and respected. In particular, an arc flash can be catastrophic, causing property damage, severe injuries, and even fatalities. But what exactly is an arc flash, what are the employer’s responsibilities, and what can be done about the associated risks? Let’s take a closer look.

What is Arc Flash?

Arc flash is a rapid and intense release of electrical energy which can happen due to a variety of conditions such as equipment failure, accumulation of dust or impurities in the air, accidental contact with energized parts, or improper maintenance of electrical systems. This release results in an explosion of light, heat, and sound, with temperatures that can exceed 35,000 °F, more than three times hotter than the surface of the sun. The heat generated by the arc flash can cause serious burns, and the sound can cause hearing damage. The pressure wave generated by the explosion can also result in physical trauma, such as broken bones or a concussion. These conditions pose a significant risk to anyone in the vicinity of the electrical equipment when an arc flash occurs, including workers who operate and maintain the equipment.

What Does an Arc Flash Study Involve?

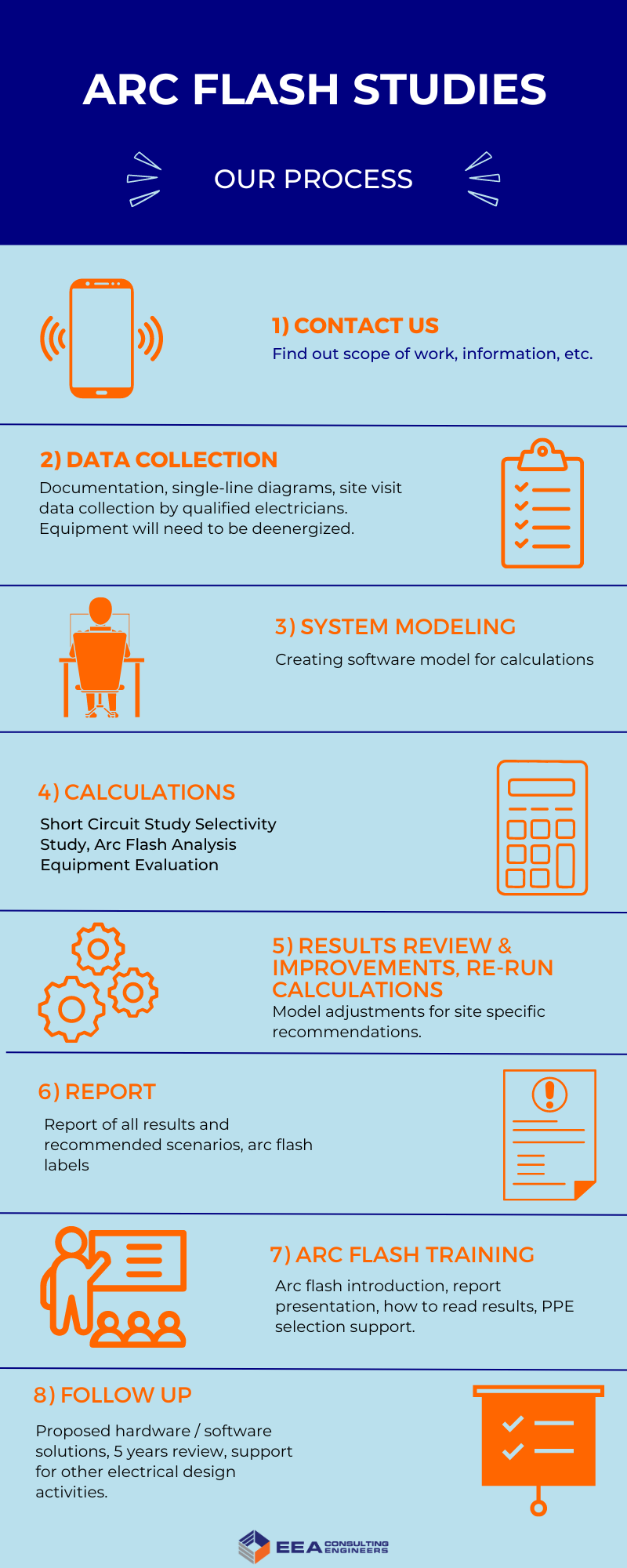

An arc flash study involves a detailed analysis of the electrical system to identify potential fault currents and the incident energy that could be released in the event of an arc flash. The study also evaluates the existing electrical protective devices, such as circuit breakers and fuses, to ensure that they can interrupt the fault current quickly and lessen the damage of an arc flash. The study may also recommend changes to the electrical system, such as adjustments to existing equipment, adding protective equipment, or upgrading the existing equipment to reduce the risk of an arc flash.

Why Are Arc Flash Studies Important?

Arc flash studies are essential for identifying potential hazards associated with the electrical system and reducing the risk of an arc flash. Both are important considerations related to the Occupational Safety and Health Administration’s (OSHA) regulations, which mandate that employers provide a safe working environment for their employees. By understanding the hazards, appropriate safety procedures can be developed for working on the system. Implementing the findings of an arc flash study in conjunction with NFPA 70E: Standard for Electrical Safety in the Workplace can help demonstrate compliance with OSHA’s regulations. In addition to OSHA compliance, arc flash studies can also help to reduce the risk of equipment damage, downtime, and lost productivity.

The Role of Personal Protective Equipment

Personal protective equipment (PPE) is an essential component of arc flash safety, as it protects workers from the thermal and physical hazards of an arc flash. An arc flash study is necessary to determine the estimated incident energy level, which is the amount of energy released during an arc flash, at each piece of equipment in the electrical system. The incident energy level will then be incorporated into an arc flash hazard label to be applied to the equipment. Along with NFPA 70E, the label will be used in the field to determine the appropriate level of PPE required, which can range from a basic set of gloves and goggles to a full-body suit with a hood and face shield.

As we have seen, arc flash is a dangerous and potentially deadly phenomenon that can occur when working with electrical equipment. Arc flash studies are the key to identifying potential hazards and reducing the risk of an arc flash. By implementing recommendations from an arc flash study, employers can provide a safer working environment for their employees and help to ensure the reliable and safe operation of their electrical systems.