National Needs

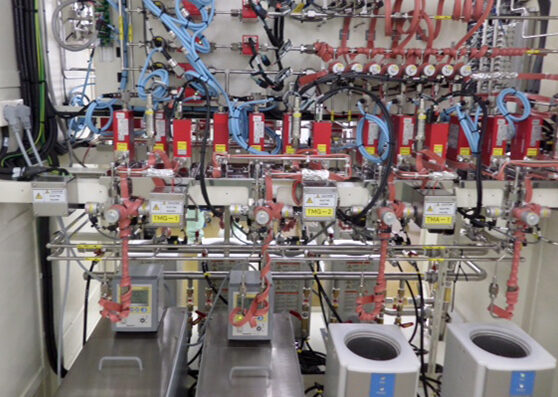

EEA assisted a confidential client which operates and maintains a semiconductor manufacturing facility in the southwest United States. As the facility and tools have aged, an extensive upgrade was required to keep the building operational and to maintain critical capability for the customer. EEA completed a master plan to document how this facility could be completely overhauled and upgraded. This involved the installation and removal of approximately 100 tools, as well as approximately 50 separate projects – all in an operational fab.

Industry Pain Points & Engineer-Led Solutions

We understand that clients often have a high sense of urgency and want a reliable engineer. Our team has worked within the parameters of existing bad designs and we know how to make the best with what’s provided. We minimize down time and fix problems quickly so the client can save millions of dollars.

Cross discipline coordination was critical to this project, especially given space constraints in the fab. In addition to traditional MEP design services, EEA managed a consultant team including process engineers, architects, structural engineers, and fire protection engineers. One of the unique challenges was planning the execution of the project given the complex nature of removing and installing tools and upgrading utility systems in a working fab. We integrated ourselves closely with the customer to develop a workable plan, which included the needs of process owners, facility system owners, and management.

Flexibility and Focus

As the project progressed, the tool set requirements for the customer evolved. In addition, down time constraints and production needs drove changes to design packages that had to be incorporated in a timely manner. EEA maintained both flexibility and focus to continue forward progress and meet the customer’s needs.