POWERFUL STUFF!

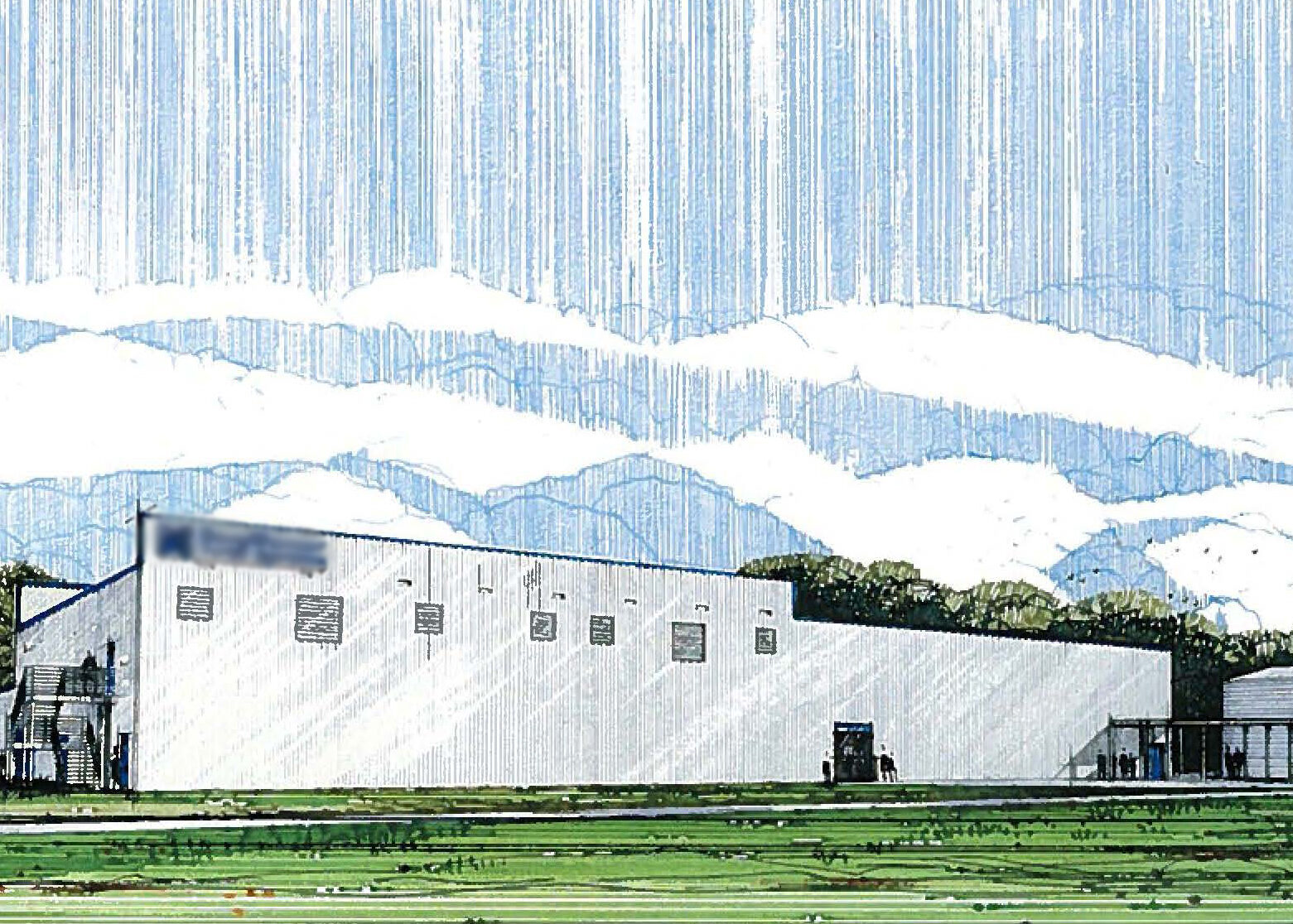

EEA has decades of electronics clean manufacturing experience, but as Monty Python would say, “And now for something completely different”! In 2000 EEA worked with an international manufacturer of automotive parts to design their new 31,000 square foot diesel engine turbocharger research and test facility. The building included a model shop for product development, bays for testing turbocharger performance, and bays for testing engine performance with the turbochargers.

How it Works

A turbocharger uses engine exhaust energy to force more air into the engine combustion chamber. This produces a significant increase in horsepower and torque, allowing smaller engines to do the same work as a much larger, normally aspirated engine. The turbo test bays used a mix of compressed air and high pressure natural gas to simulate the high energy/high temperature (up to 1,400 Fahrenheit!) exhaust stream, and then measure the air pumping efficiency of the turbocharger under different load conditions. The engine test bays were designed for dynamometer testing of up to 500HP engines fitted with the new turbochargers. EEA designed the MEP and process utility systems for the new facility, including diesel fuel storage and distribution, engine cooling water with cooling towers for heat rejection, and engine exhaust.

Unique Situation

The location of the new test lab was across the street from an elementary school with a 50 decibel sound limit at the property line. EEA worked with an acoustics specialist to design an exhaust system for each test bay with two mufflers in series, one for low frequencies and one for higher frequencies. As you can imagine, accommodating thermal expansion at 1,400 degrees was also a critical factor. When completed, we could stand next to the 10” exhaust pipe on the roof and hold a normal conversation. Needless to say, there were no complaints from the elementary school.