Rising to Meet Your Demands

With the increased use of technology in everyday life and the advent of Artificial Intelligence (AI), the need for Data Centers has grown at a rapid pace. The amount of power needed and the heat generated increases with computing power.

EEA has experience designing new ground up data centers, as well as designing complex upgrades and expansions to existing data centers. We work closely with our clients to develop thoughtful solutions to key challenges including:

- Minimizing impacts to existing operations

- Driving down Power Usage Effectiveness (PUE) through energy efficient design

- Maximize uptime with system resiliency and redundancy

Our relevant design capabilities include:

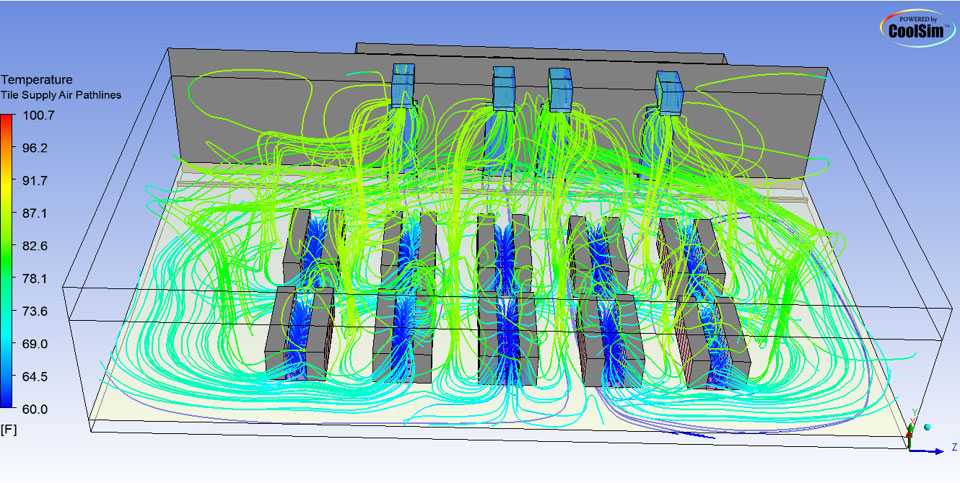

- Hot Aisle / Cold Aisle Containment

- Underfloor Air Distribution

- Chilled Water Systems

- Process Cooling Water Systems for Liquid Cooled Racks and Immersion Cooling systems

- Evaporative Cooling

- Back-Up Power including Generators and Uninterpretable Power Supply (UPS)

- Sensitive Compartmented Information Facility (SCIF) Environments

Photo Credit: Applied Math Modeling

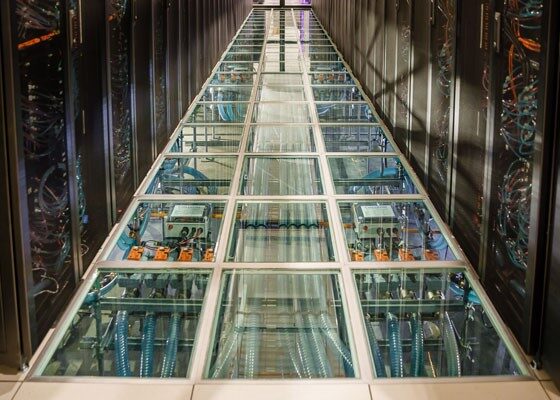

Liquid-Cooled Solutions

As data center computing technology evolves, there will be an increased shift towards liquid cooling as power density increases. EEA is experienced in engineering liquid cooling solutions for data centers, including fluid coolers, hybrid fluid coolers, thermosiphons, and immersion cooling.

Our Experience

Data Center XDP Refrigerant Manifold Optimization

EEA provided design to optimize the layout of overhead refrigerant piping manifolds associated with three (3) rack rows and approximately 45 individual cooling modules/racks served by Leibert XDP refrigerant pumping units. The client required optimization of rack row layouts with the addition of several air-cooled rack rows which subsequently left refrigerant manifolds abandoned overhead. This project provided a phased construction approach to keep the maximum number of racks in operation possible to minimize downtime.

Data Center HVAC Upgrade (Heat Exchanger)

This project was primarily electrical scope, but the mechanical scope included installing a new heat exchanger to serve an existing process chilled water (PCW) loop. The heat exchanger was located in the mechanical room. The biggest challenge of the project was coordinating the new pipe routing with the existing utilities in a congested mechanical room. The project included two alternatives for connecting the new PCW piping to the existing loop, with a design analysis narrative of each option to assist the client in selecting their preferred method of connecting the new heat exchanger to the existing PCW loop.

Data Center Expansion

A data center client requested to increase their total cooling load to 14 MW, without using chilled water. EEA designed the addition of a new process cooling water system, including six 900-ton fluid coolers and three 125 HP pumps, which were connected to an existing process chilled water system located in the underfloor plenum of the data center. The data center did not have space for these new units, and as such a new elevated platform was designed outside of the building, where all of the new equipment was located. For the airside component of the cooling, EEA designed the addition of one custom air handling unit and three exhaust fans to allow for additional airside cooling along with economizer mode for efficiency. The largest challenge of the project was the pipe routing at the elevated platform and in the underfloor plenum, both of which were very constrained due to other utilities occupying the same spaces. By switching the cooling for the process chilled water from chillers to fluid coolers, the data center was able to greatly reduce its PUE. EEA coordinated directly with the installing contractors during construction to ensure project success.

Data Center XDP Unit Chilled Water Backup Feed

EEA provided design FOR a backup chilled water feed to the pumps serving Leibert XDP pumping units within an existing Data Center space. The data center chilled water pumps were served by a water cooled chiller plant in a nearby Central Utility Building (CUB), but the client desired additional redundancy and emergency backup capabilities for the computer racks served by the XDPs. The building housing the data center had an existing chilled water supply line from an alternate chilled water source at another nearby CUB that was rarely used for the building Air handling systems. Due to budget constrains prohibiting installation of new full capacity chilled water piping from the alternate chilled water source, the smaller existing chilled water supply and return lines were chosen as emergency backup sources to allow for partial cooling of up to 60% of full rack load. EEA faced challenges with the routing of new piping within a very crowded mechanical space and complicated piping system which required the installation of several new automated control valves which would allow for the isolation of the XDP pumps from the primary chilled water source and automated or manual switchover to the backup chilled water source.

Data Center HVAC Upgrade (Thermosiphon & Exhaust Fan)

EEA designed the addition of a new load-shedding thermosyphon and a large exhaust fan at a data center located in a Vault Type Room (VTR) environment. The thermosiphon and exhaust fan were located on the roof of the data center. The client requested zero downtime during the install, which was possible for the thermosiphon but not for the exhaust fan as it required roof cutting over the data center. The exhaust fan was connected via ductwork to an existing air handling unit and allowed the air handling unit to go into economizer mode to reduce energy consumption. The new thermosiphon allowed the data center to be more energy efficient by reducing the chilled water load of the building when ambient conditions allow.

Electrical Resiliency Upgrade

EEA designed the replacement and upgrade of the electrical distribution system at a data center located in a SCIF environment. This involved providing multiple redundant power feeds from different substations to eliminate single points of failure. The client required minimizing downtime and maximizing availability during the replacement. This included maintaining redundant power to the data center throughout construction by using an existing generator set and a temporary set. The design was phased to plan for the removal of existing equipment and installation of new equipment. Resiliency for the data center was provided in the form of 2N redundant Uninterruptible Power Supplies (UPS) and multiple tie breakers between the redundant distribution equipment.

UPS Replacement

EEA designed the replacement of the existing 2N redundant Uninterruptible Power Supply (UPS) system at a data center located in a SCIF environment. The design package addressed construction sequencing to minimize impact to the data center 24/7 operations. This included a Risk and Gap Analysis. The project intent was to support concurrent maintenance and enable an independent Side A and Side B distribution system throughout the data center.

Power Upgrade

EEA analyzed a client’s medium voltage distribution system and designed the extension of 4MW of redundant power to an existing data center that was reaching the limits of the available power capacity in the facility. This involved integrating new feeder bay switchgear and controls at two medium voltage substations and planning feeder routing, medium voltage electrical gear placement, and low voltage penetrations into a VTR-like space. In addition, this project integrated new humidification control capabilities to the data center space, and designed power and water cooling to a new very high-density high-performance computing system that consumes nearly 2MW of power on its own. EEA coordinated with multiple customer, site, and facility groups to ensure a successful outcome in this highly complex project.

Utility Extension

EEA designed the installation of additional PDUs and CDUs for a new high-performance computing system in an existing VTR-like data center space. To minimize impact on data center operations, it was determined that hot-tapping existing chilled water sources was the preferred method of extending chilled water supply and return to the new CDUs. In addition, some existing electrical system deficiencies were identified to be addressed during the project and work was able to be phased so that no active computing systems would need to be taken offline.

Data Center HVAC Upgrade

EEA designed the replacement of an unreliable custom DX system at a data center located in a SCIF environment. The client required zero downtime during the replacement, including maintaining redundancy throughout construction. In addition, additional ductwork and piping penetrations were not allowed through the SCIF barrier. Other challenges included a very constrained space inside the data center, and in the associated mechanical equipment area. EEA designed a replacement system utilizing air-cooled chillers and air handlers with a variable primary chilled water system. Redundancy was maintained throughout construction using a temporary chiller and carefully executed plan to remove existing equipment and install new equipment in a phased manner. The replacement system was more reliable and more energy efficient. Computational Fluid Dynamics (CFD) modeling was utilized to ensure proper airflow through the cold aisle as extensive ductwork modifications were not possible due to the constrained space. EEA integrated closely with the client to ensure a successful outcome.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

EEA specializes in designing innovative and resilient infrastructure solutions for data centers, with expertise in cooling optimization, electrical resiliency, and system redundancy. Our team has successfully executed complex projects, including refrigerant manifold optimization, chilled water backup integration, and large-scale HVAC upgrades, all while minimizing downtime in mission-critical environments.

We excel in power distribution enhancements, such as extending 4MW of redundant power and upgrading UPS systems to support 24/7 operations. By leveraging phased construction strategies, advanced control systems, and energy-efficient designs, we help clients improve performance, reliability, and sustainability. Our collaborative approach ensures seamless coordination with stakeholders, delivering tailored solutions for high-performance computing and data center expansions.

We are known for our responsiveness and welcome an open line of communication with our partners. Let us know how we can partner with you.

-

This data center is currently designed for 7 MW (1991 tons) of computers, using a nearby CUB (chillers) to provide cooling. Phase 1 of the...

This data center is currently designed for 7 MW (1991 tons) of computers, using a nearby CUB (chillers) to provide cooling. Phase 1 of the... -

Expansion of Data In 2012, a client had an existing data center that had reached capacity after opening only two years prior. This data center was...

Expansion of Data In 2012, a client had an existing data center that had reached capacity after opening only two years prior. This data center was...